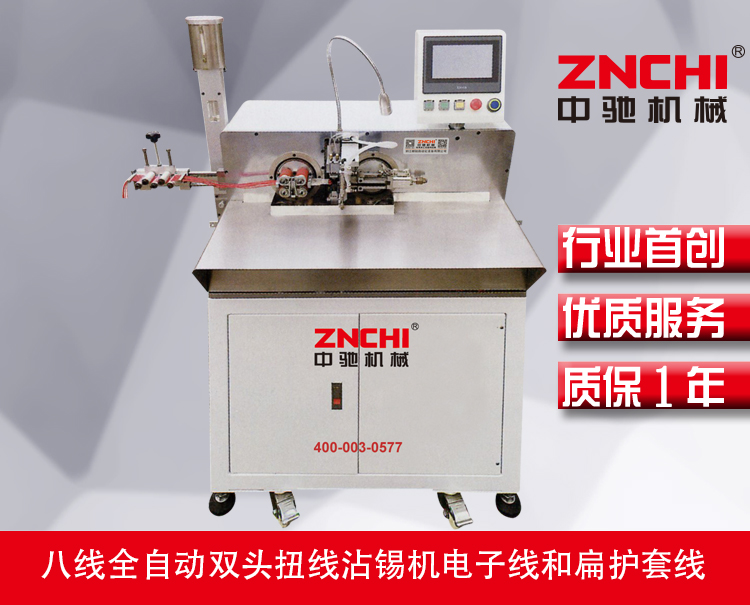

精巧、紧凑的设计、极佳的构思、占地面积小。

模块化设计,使调机维护和传统机械式相比有着很大的优势,电脑触摸中文操作菜单,裁线长度、剥皮长度、扭线长度、沾锡机深度、沾锡机时间等任何参数均可在屏幕上调节,易学易用,更换工序和材料迅速省时省力,弥补了传统及其需专业师傅,调机难,不稳定诸多问题。

沾锡深度、沾锡次数可屏幕调节,满足沾锡线材的各种高难度要求,沾锡为90°点沾,沾锡深度准确,沾锡厚度均匀,沾锡效果完美。

高效的步进驱动,整机配件电镀处理保证不易生锈,配件均采用高精密度加工,保证了线材的精度。快速度,同时可加工多条线材效率高。

加有废料吸气装置,在保证机器整洁干净无废料的情况下也避免了切断铜丝的缺点,维护方便。

高配置,高产量,高性价比。

本公司提供培训、安装、调试、保养、维修一条龙服务。

Smart, compact design, excellent design, cover an area of an area small.

Modular design, make the machine maintenance and there is a big advantage in comparison to the traditional mechanical, Chinese computer touch screen menu operation, line length, stripping length, twisted wire cutting length, the wetting machine depth and wetting machine time any parameter adjustment on the screen, easy to learn and easy to use, change process and material time, quickly make up for the traditional machine needs professional chesf,adjustable machine, unstable, and many other problems.

Numner wetting depth and wetting can adjust the screen, meet all kinds of tough demands that dip tin wire, tin is 90°points even touched, wetting depth accurately, wetting uniform thickness, wetting effect is perfect.

The highly effective stepper driver, machine accessories electroplating processing guarantee is not easy to rust, accessories adopt high precision processing, ensure the accuracy of the wire. Fast speed, multiple wire high efficiency can be processed at the same time.

With waste suction device, ensure the neatness of machine clean Without waste also avoids to cut off the wire fault, maintenance is comvenient.

High configuration, high yield, high cost performance.

The company provides training, installation, commissioning, maintenance, repair through-train service.

型号 电源 功能 产能 可加工电线 切断长度 剥口长度 扭线长度 沾锡长度 空气压力 机体尺寸 机体重量 | AC220V/50/60HZ单相 电线切断、单端削皮扭线、单端压着 AWG30#--AWG26#剥8线速度为22000条/H(裁线长度为200mm以下)AWG18#裁线四根生产能力根据电线的种类、尺寸而变化电子线直径:0.3MM-3.0MM(AWG30#--AWG18#) 11mm~9999mm 0.0mm~10mm 3.0mm~10mm 1mm~10mm 6kgf (需使用清洁干燥空气) 6 KGF ( Need to use clear dry air) 670W×840L×1200H(mm) 约310kg About 310kg |

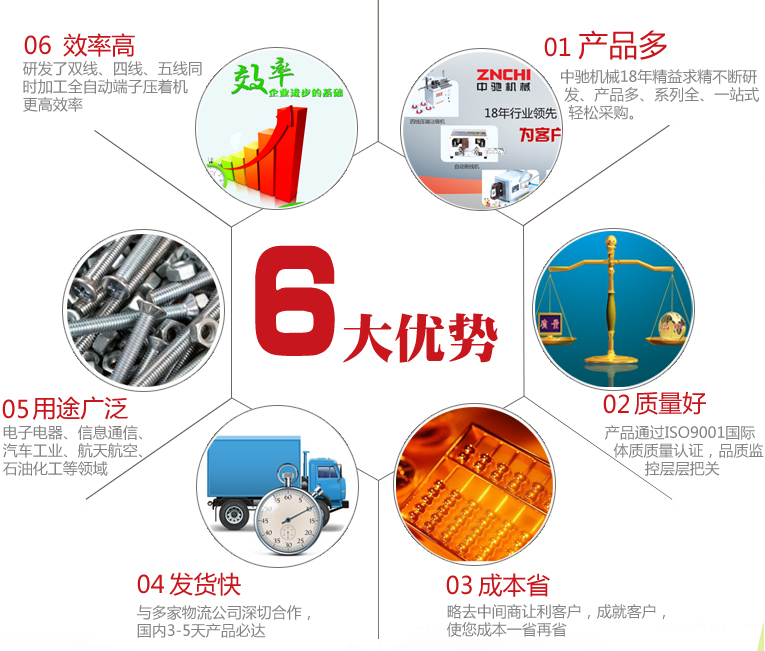

精驰优势

精驰合作客户

|  |  |  |  |

精驰伙伴-利欧股份 | 精驰伙伴-美的 | 精驰伙伴-格力 | 精驰伙伴-奥克斯 | 精驰伙伴-正泰集团 |

联系精驰

浙江精驰自动化设备有限公司

浙江精驰自动化设备有限公司

咨询热线:400-003-0577

企业传真:0577-61756350

企业邮箱:4000030577@b.qq.com

公司地址:乐清市柳市镇中心大道与柳翁路交叉口桥后村办公楼8楼(鼎大家居8楼)

| * 联系人: | 请填写您的真实姓名 |

| * 手机号码: | 请填写您的联系电话 |

| 电子邮件: | |

| * 采购意向描述: | |

| 请填写采购的产品数量和产品描述,方便我们进行统一备货。 | |

| 验证码: |

|

| 我要评论: | |

| *内 容: |

(内容最多500个汉字,1000个字符) |

| 验证码: | 看不清?! |

联系精驰自动化

咨询热线:400-003-0577- 销售电话:0577-62766667

- 18334433285

- 售后电话:400-003-0577

- 0577-62766668

- 18868285633

- 传真:0577-61756350

- 邮箱:4000030577@b.qq.com

- 地址:浙江乐清市柳市镇中心大道与柳翁路交叉口桥后村办公楼8楼(鼎大家居8楼)

共有-条评论【我要评论】